Impact of simulations early in product development

- SimulaX

- Jun 9, 2025

- 2 min read

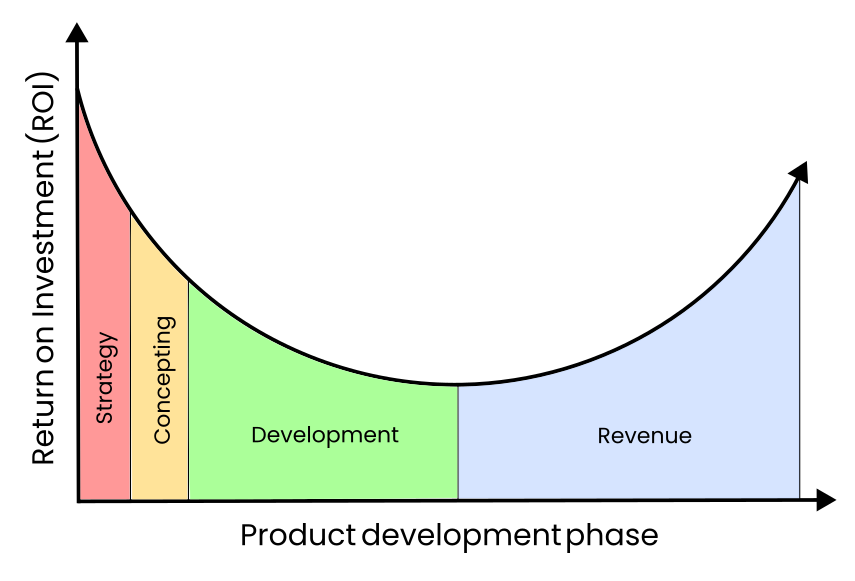

In product development, the early stages are where the most critical decisions are made—long before a physical prototype is ever built. Studies show that over 70% of a product’s total cost is committed during the design phase. This means that identifying and addressing design issues early in concepting can have a significant impact on both performance and profitability.

Engineering simulation, often referred to as virtual testing, allows teams to do exactly that.

Physical prototyping and engineering simulations

Instead of relying solely on physical prototypes or late-stage testing, simulation provides insight into how a product will behave under real-world conditions—from structural loads and thermal effects to fluid flow and electromagnetic behavior. With the right models in place, it’s possible to test dozens of design variations, explore “what-if” scenarios, and evaluate the impact of changes in geometry, material, or boundary conditions—all without waiting weeks or months for hardware.

Simulation isn't just about predicting failure. It's also about enabling better design choices: lighter components that are still strong enough, more efficient cooling, reduced vibration, or better material usage. When used consistently and early in the design process, simulation reduces risk, shortens development cycles, and limits the need for expensive, time-consuming trial and error.

SimulaX engineering

While simulation tools are powerful, they require experience to be used effectively. It’s not just about software—it’s about applying engineering judgment to simplify complex models, interpret results, and make meaningful design decisions.

During a previous project, SimulaX engineering collaborated closely with JJ Xray to strengthen their development and validation processes through advanced simulations. We partnered with their team to provide additional expertise in key areas such as eigenfrequency analysis, thermal performance evaluation, and design optimization. By simulating and comparing multiple design variants early in the process, we helped them validate performance targets more efficiently.

For example, we supported the rotor blade design, optimizing it for increased stiffness while maintaining the center of gravity. This helped reduce design time and iteration cycles significantly.

With our involvement, the client was able to move forward faster—with greater confidence, and technical insight.

Have a similar problem? Reach out — we’d love to hear from you and explore how we can support you.

Comments